Overhangs are annoying. When 3D printing, you must be cautious to avoid having an overhang of more then a few dozen degrees, and if you do, you must support it with extra support material. This material is annoying to remove and makes the print take longer.

Recently, a few new techniques to print overhangs without support have been popularized. Conical slicing and arc overhangs are two new ideas that allow the printing of overhangs basically by always pulling filament against an already printed surface. I discovered these ideas from two excellent videos by CNC Kitchen.

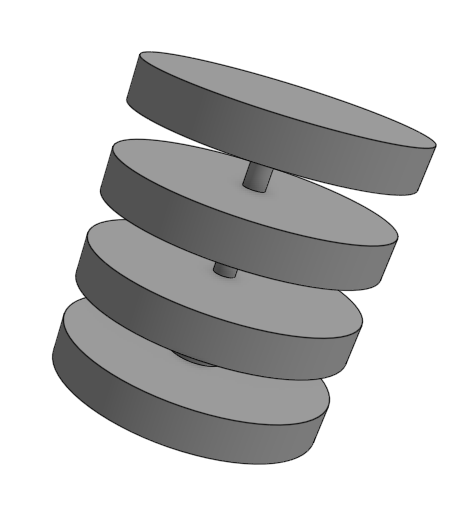

For one of my high school engineering projects, I needed a roller, which was basically a stack of

differently-sized circles on top of each other:

The Journey

This project was nicely timed so that I could take on this challenge over winter break and put a lot of time into it. I decided to try to write this G-code generator is Rust, because I’ve been meaning to learn the language for a while. I really enjoyed the experience and found Rust a joy to use. The compiler feedback is impeccable, the integration with VS code works great, and the speed is a nice bonus when I’m trying to get working code and don’t want to spend time optimizing my algorithms. My code is available at github.com/rivques/FunWithOverhangs and should be pretty plug and play.

Simple beginnings

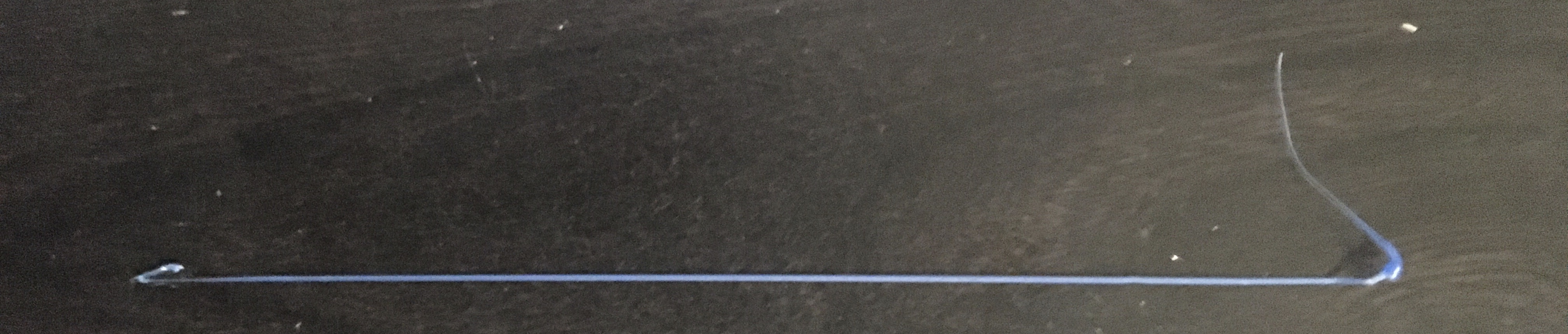

I started by just trying to extrude a line across the build plate. I was initially using the gen_gcode

crate, but I quickly realized that it would not be sufficient enough for my needs. Its Point3d type didn’t support

any linear algebra operations, so it was a pain to do things like get the distance between two points, and it

didn’t support all the G-code that I wanted to use. I suspect its author wrote it to support exactly as much as they

needed and no more, and they needed less than me. To fix this, I wrote my own module to handle G-code generation that does

exactly as much as I need and fixes a few of the issues I was having with gen_gcode. Even after I was generating coherent

G-code, I still wasn’t able to get any extrusion. I figured my math to find how much I should extrude per millimeter I moved

was off. Even after fixing a confusion of the radius of the filament with the diameter, it still wasn’t working. I had a hunch that

it might have something to do with the long Bowden cable not having enough time to build up the pressure to extrude filament.

Sure enough, longer lines worked enough that I was willing to push ahead.

Cylinders

I next tried to generate a circle. A quick bit of research confirmed that there was a spiral with a consistent distance between its lines. The Archimedean Spiral, with the conveniently simple formula $r=aθ$, has a consistent inter-line spacing of $2πb$. It was fairly simple to plug my line width of $0.4$mm into this, then loop over $θ$ for however many rings were needed to achieve the desired diameter. One issue I ran into was that Rust doesn’t support iterating over a range with a non-integer step, so instead of iterating in radians I iterated in degrees then immediately converted them to radians. Here’s my code for this, with a few modifications for clarity (again, the whole program is on my Github):

for theta_deg in (0..(360*(diameter/2.0/line_width).floor() as i32)).step_by(5) {

let theta = theta_deg as f64 * PI / 180.0; // convert theta to radians

let r = (spacing / (2.0*PI)) * theta; // compute r

let point = point3!(r*theta.cos() + starting_location.x, r*theta.sin() + starting_location.y, printer.position.z);

printer.extrude_to(point) // automatically calculate the needed extrusion

}

After I had a circle, it was easy to stack a few on top of each other, and now I was making cylinders!

Mushrooms

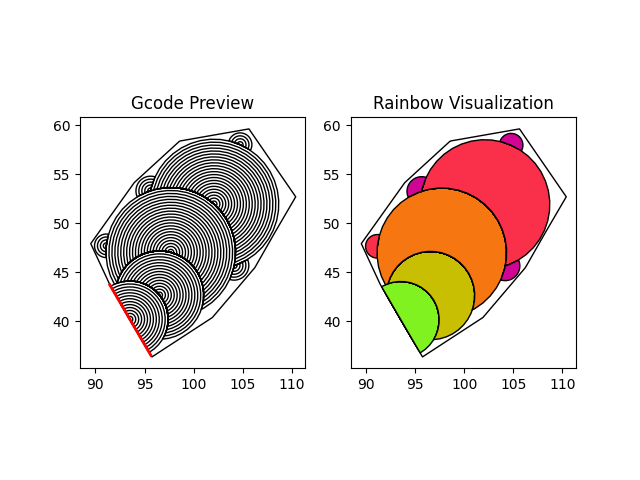

By stacking cylinders, I was able to generate a mushroom. This was the first time I actually did any supportless overhangs. I made

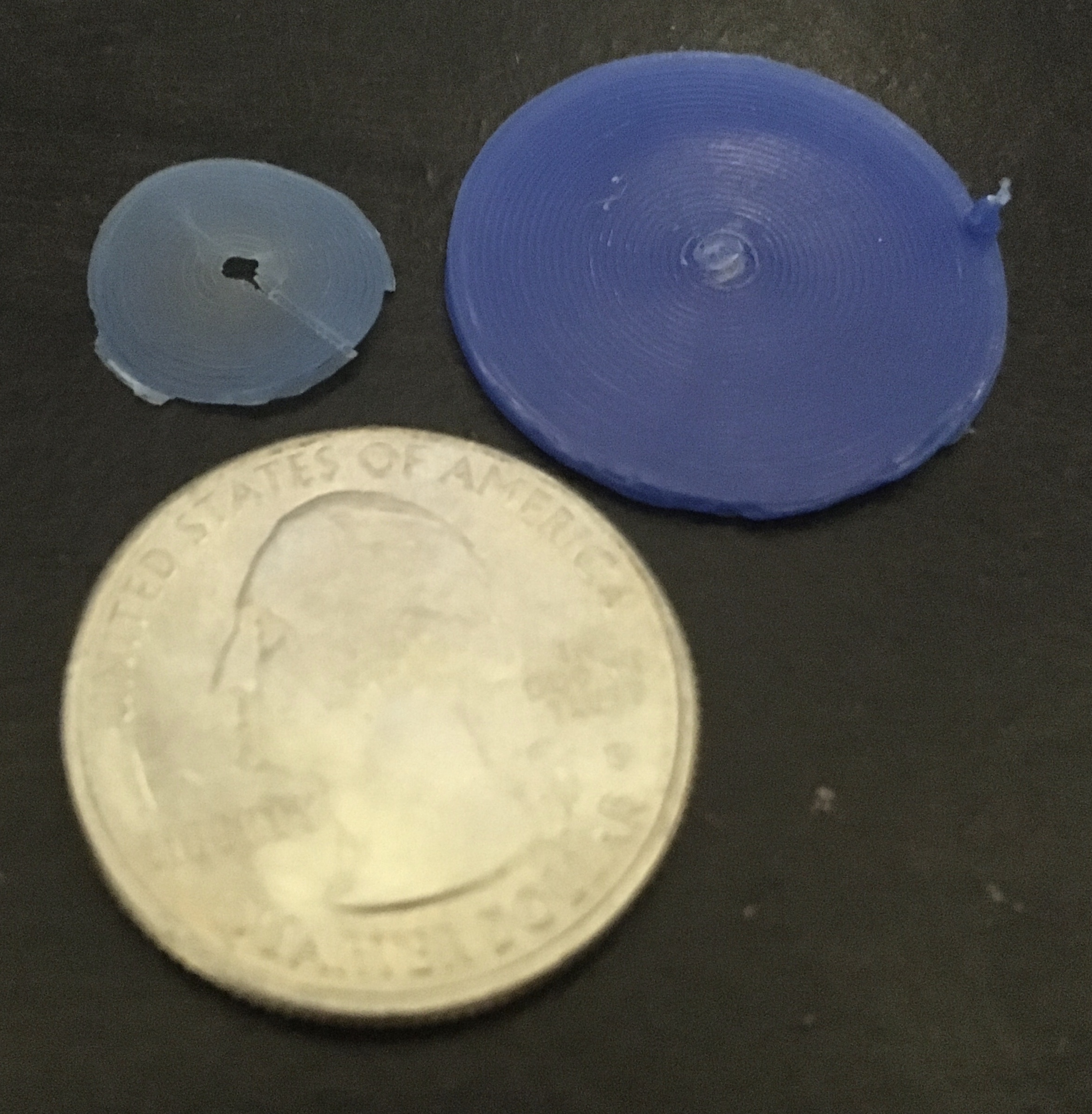

some guesses at how much overlap would be needed, which were close but not quite right:

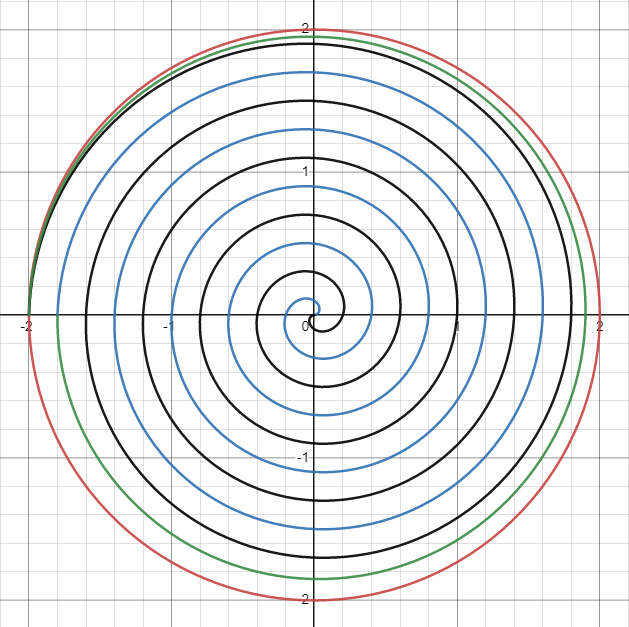

Spiral Easing

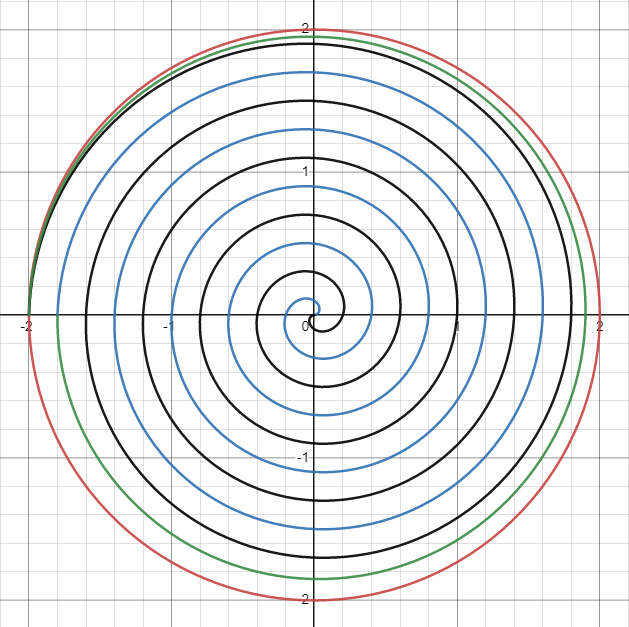

Because the toolpath is generated from a spiral, the circumference is not consistent and has a sharp jump where the spiral ends. After playing

around in this Desmos calculator I found a polar equation that nicely averaged between the spiral

and a perfect circle:

To Bigger and Better Things

Now that I had some nice mushroom-generating code, I tried to change some of the parameters to better fit my initial roller design.

I had to abort the first print out of the printer: